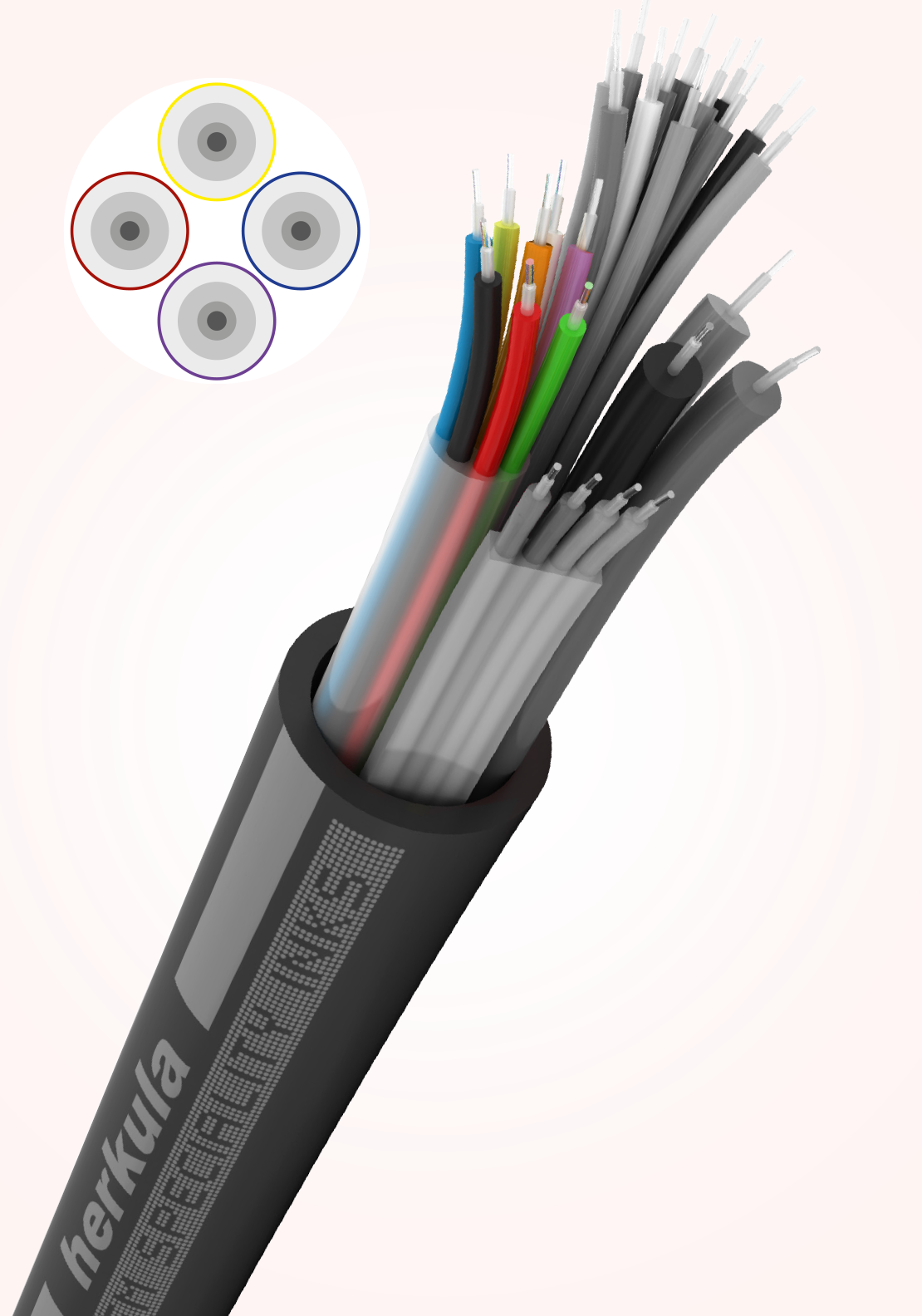

Since the start of the industrial production of optical fibre cables, Herkula is a supplier of special UV Inks and UV Matrix Materials to the industry throughout the world. The ink is necessary to ensure the distinction of optical fibres. Today, the product line FibreCoat is an important segment of Herkula. Over the years the product portfolio has been supplemented by further Matrix Materials for optical fibres such as Tight Buffer, Compact Fibre Unit and Ribbon.

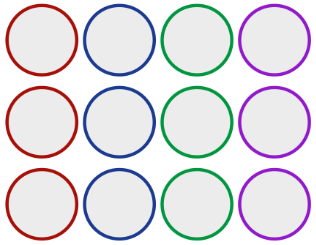

Our UV Ink can be used on every colouring line that is available in the market, and you can reach a line speed of up to 3000m/min. The cured Ink has a very good slip and surface finish, these properties support a robust production process so that e.g. the take up runs smoother. The 12 standard colour shades fulfil all specifications according to Munsell, BT and FT, and on request we can provide 4 additional shades. We are glad to announce that our FibreCoat inks are fully compatible with UV-LED curing lamps.

| Series | Line Speed M/Min | Application | PROPERTIES |

|---|---|---|---|

| 813F | < 3000 | UV curing system | Chemical and mechanical resistant |

| 820 | < 3000 | UV-LED curing system | Chemical and mechanical resistant |

Herkula also offers UV and UV-LED Tight Buffer Matrix Materials. You can use our UV Tight Buffer materials as a single coating or as inner & outer coating. The advantage of a single coating on the one hand is that the processing is easier, on the other hand with the combination of an inner & outer coating you achieve a better strippability for a smooth installation of the finished cable. With our UV material you can reach a line speed of up to 1000 m/min. The Tight Buffer materials are available in different kinds of softness and several colour shades. Finally, we want to inform you that selected Tight Buffer materials are available with flame retardant und high temperature resistant properties.

| Series | CHARACTERISTICS | DEGREE OF HARDNESS | |

|---|---|---|---|

| Single Coating | 831/816 | High bending modulus/ blown fibre | |

| 834/815 | Flame retardant with high bending modulus | ||

| 827F | Balanced mechanical properties | ||

| 833 | Flame retardant with soft bending modulus | ||

| 830/812 | Soft bending modulus | ||

| Outer coating | 831/816 | High bending modulus/ blown fibre | |

| 831/814 | High bending modulus | ||

| 831/815 | High bending modulus | ||

| 834/815 | Flame retardant with high bending modulus | ||

| 827F | Balanced mechanical properties | ||

| 833 | Flame retardant with soft bending modulus | ||

| Inner Coating | 830/801 | Improved strippability | |

| 830/807 | Improved adhesion |

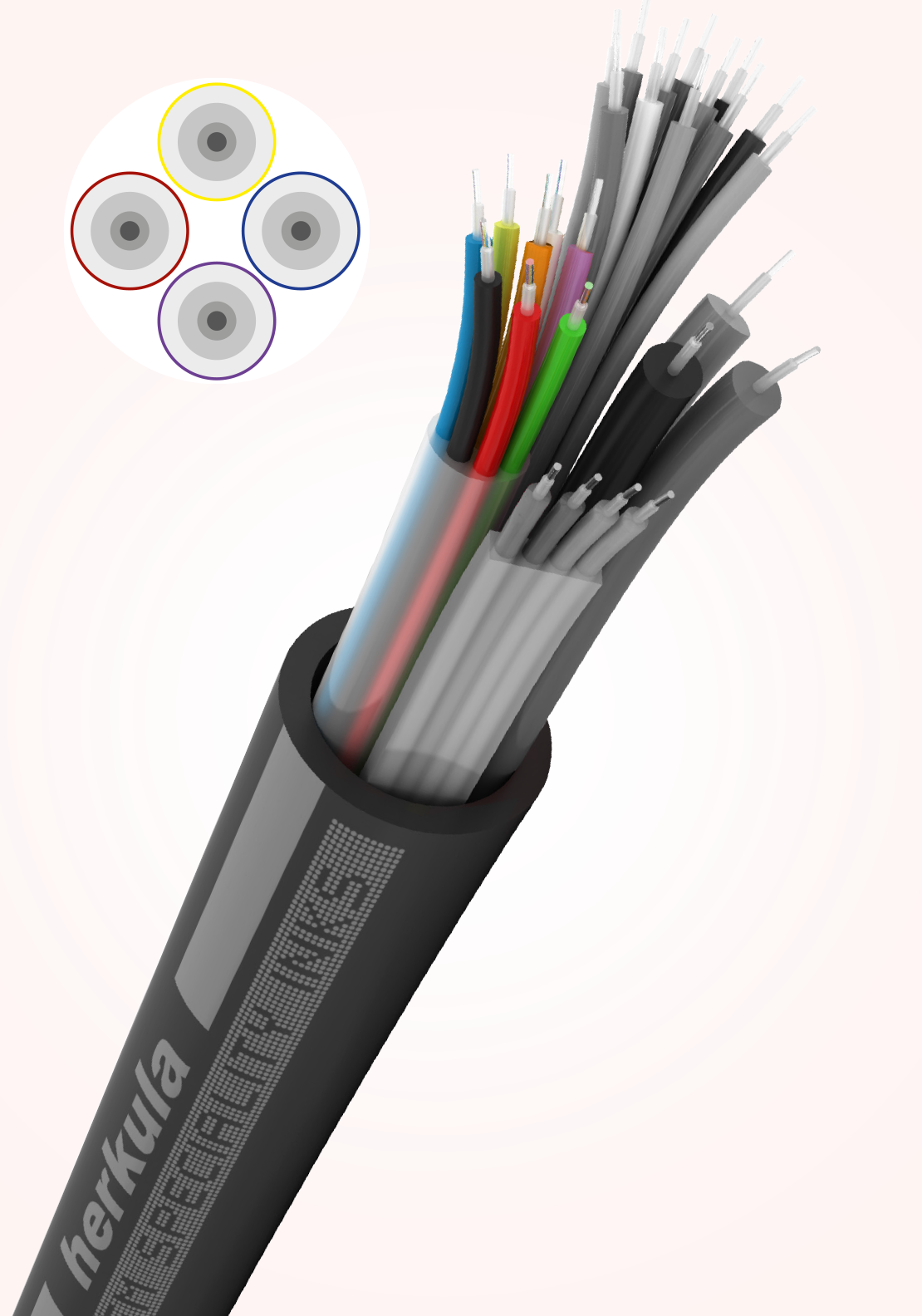

To create a Compact Fibre Unit a multi fibre coating and curing system is required. With this kind of system, you can place multiple fibres closely to each other in a circular structure and coating them with our UV or UV-LED Matrix Material. A single CFU can contain up to 12 fibres. The line speed depends on the fibre count. The space saving CFU structure allows for optimum use of space and weight in the cable. Our materials offer an excellent strippability to support a smooth installation of the finished cable.

| Series | CHARACTERISTICS | DEGREE OF HARDNESS | |

|---|---|---|---|

| Single Coating | 831/816 | High bending modulus/ blown fibre | |

| 834/815 | Flame retardant with high bending modulus | ||

| 827F | Balanced mechanical properties | ||

| 833 | Flame retardant with soft bending modulus | ||

| 830/812 | Soft bending modulus | ||

| Outer coating | 831/816 | High bending modulus/ blown fibre | |

| 831/814 | High bending modulus | ||

| 831/815 | High bending modulus | ||

| 834/815 | Flame retardant with high bending modulus | ||

| 827F | Balanced mechanical properties | ||

| 833 | Flame retardant with soft bending modulus | ||

| Inner Coating | 830/801 | Improved strippability | |

| 830/807 | Improved adhesion |

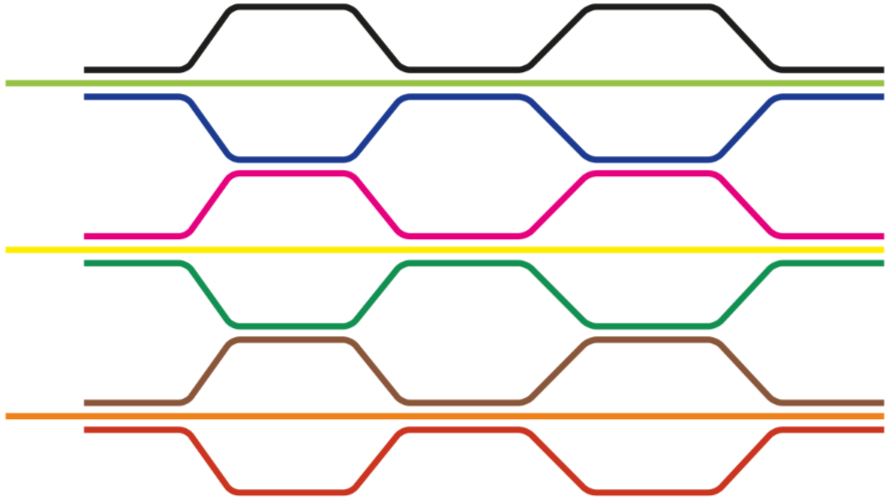

Standard Ribbon –

To apply our Matrix Material onto fibres, a ribbon line is required. With such a Ribbon line you can place the

fibres side by side next to each other and coating them with our UV Matrix Material. A standard Ribbon can contain up to 24

fibres and they can get stacked up to a height of 22 layers. The line speed depends on the fibre count. Our materials offer an

excellent strippability to support a smooth installation of the finished cable.

Flexible Ribbon –

A special UV-LED curing line is necessary to achieve this Flexible Ribbon structure. Compared to the standard

Ribbon system the fibres are only bonded selectively with our Matrix Material. This flexible structure allows to fix 16 fibres in the

cable for optimum use of space and weight. Due to the selectively placed bonds, a smooth installation can be enabled.

| Series | CHARACTERISTICS | Application | CROSS SECTION |

|---|---|---|---|

| 827 F | Standard modulus Ribbon | UV curing system |  |

| 829 | High Flexible Ribbon | UV-LED curing system |  |

In this brochure you can find an overview of our different product series.

Director Sales & Marketing

j.malige[at]herkula [dot] com